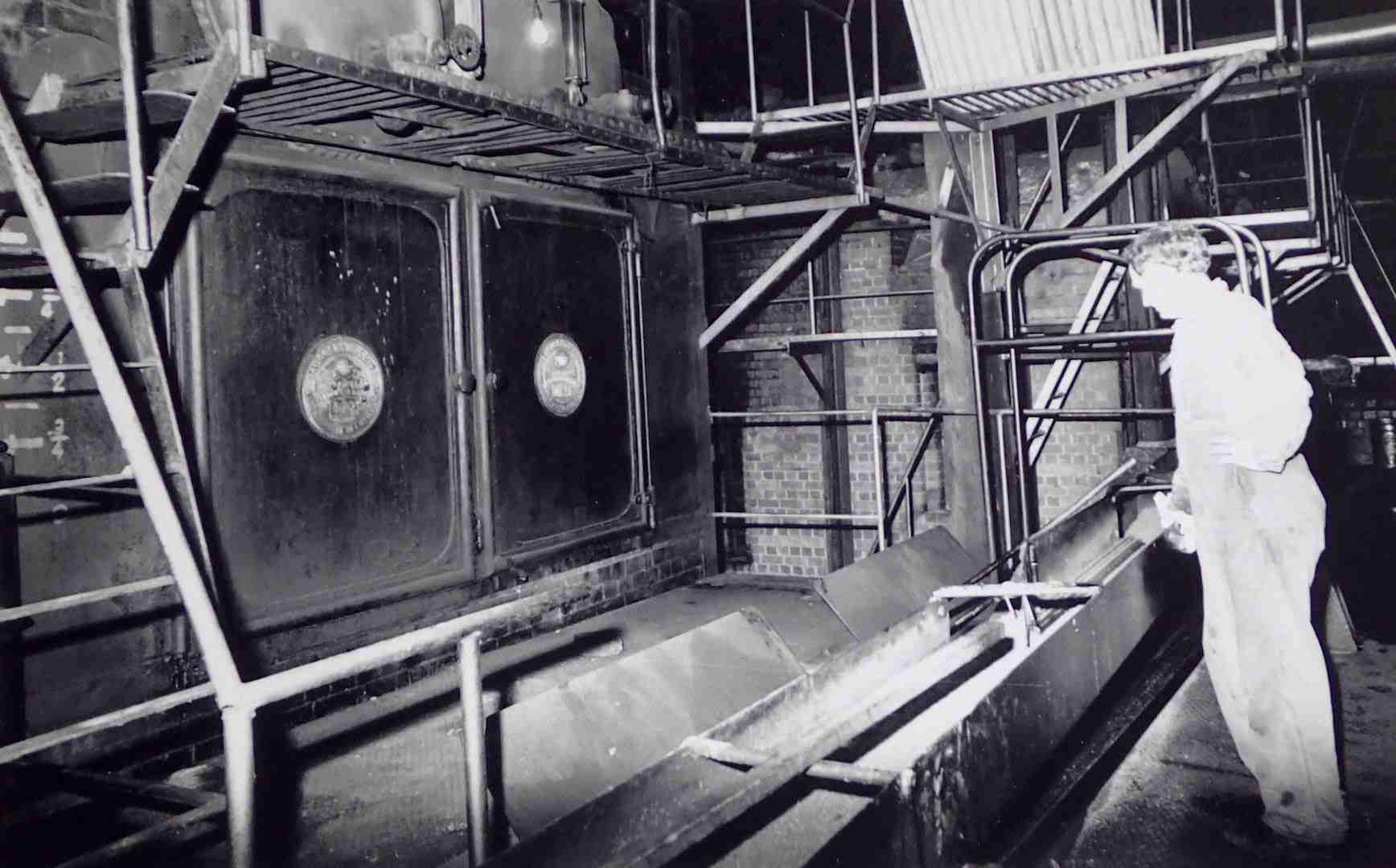

The Mill was equipped with a complete range of timber processing machinery, with a twin saw, 5 saw benches, two overhead saws, moving log carriage, four docking saws, power operated skids and rollers for the movement of timber through the mill, conveyors for the movement of sawn timber to the yard and off-cuts to the packing case area or fire hole, and conveyors for the movement of sawdust to the boilers or fire hole. Nearly all this equipment was operated by a system of shafts, belts and friction transfers operated from a single steam engine utilising steam generated by four boilers.

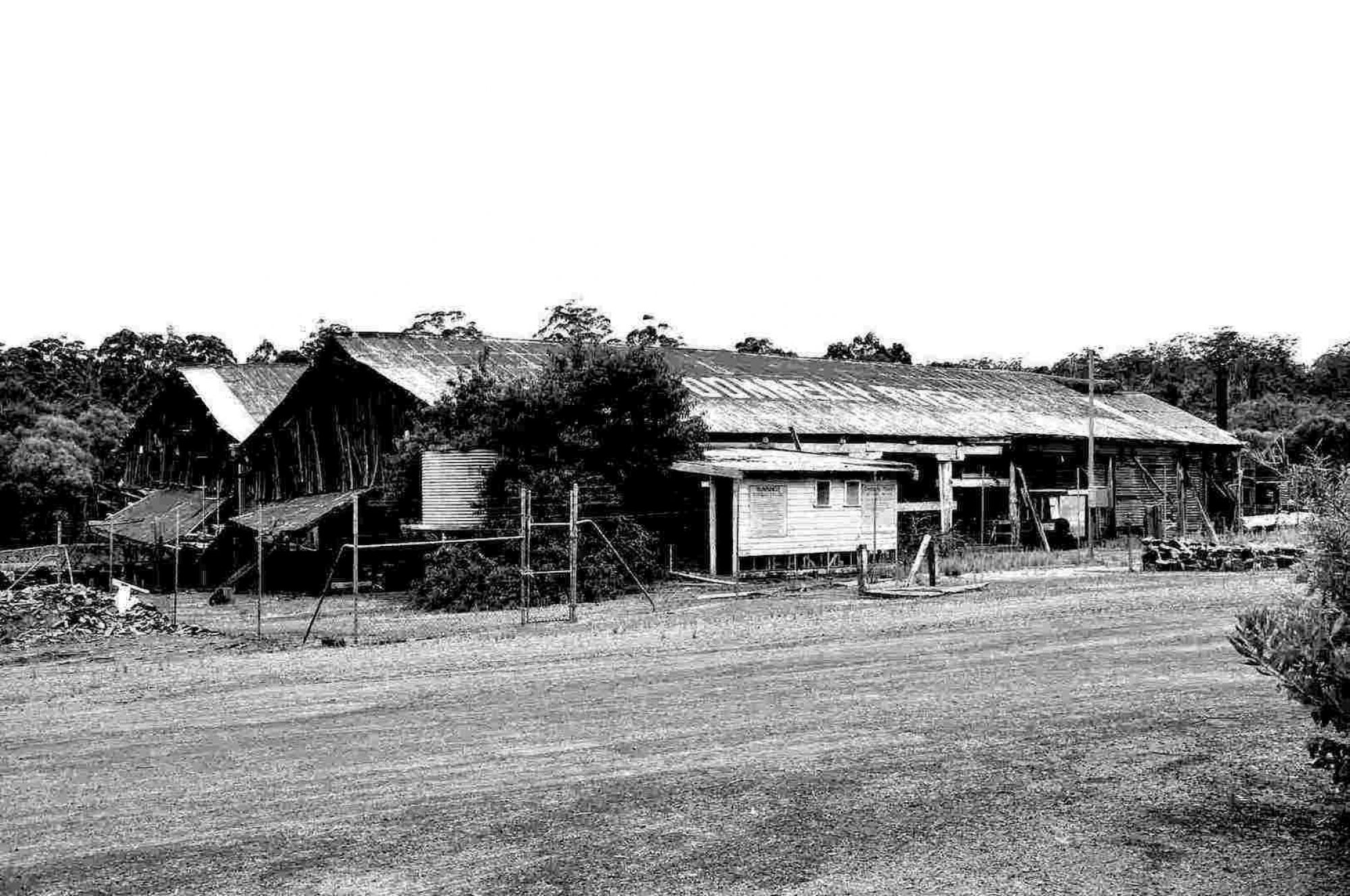

The process of milling timber using steam technology at the Donnelly River Mill may be divided into five operational systems as; Steam Generation, Power Generation, Log Handling & Milling, Waste Management, Sawdust Handling.