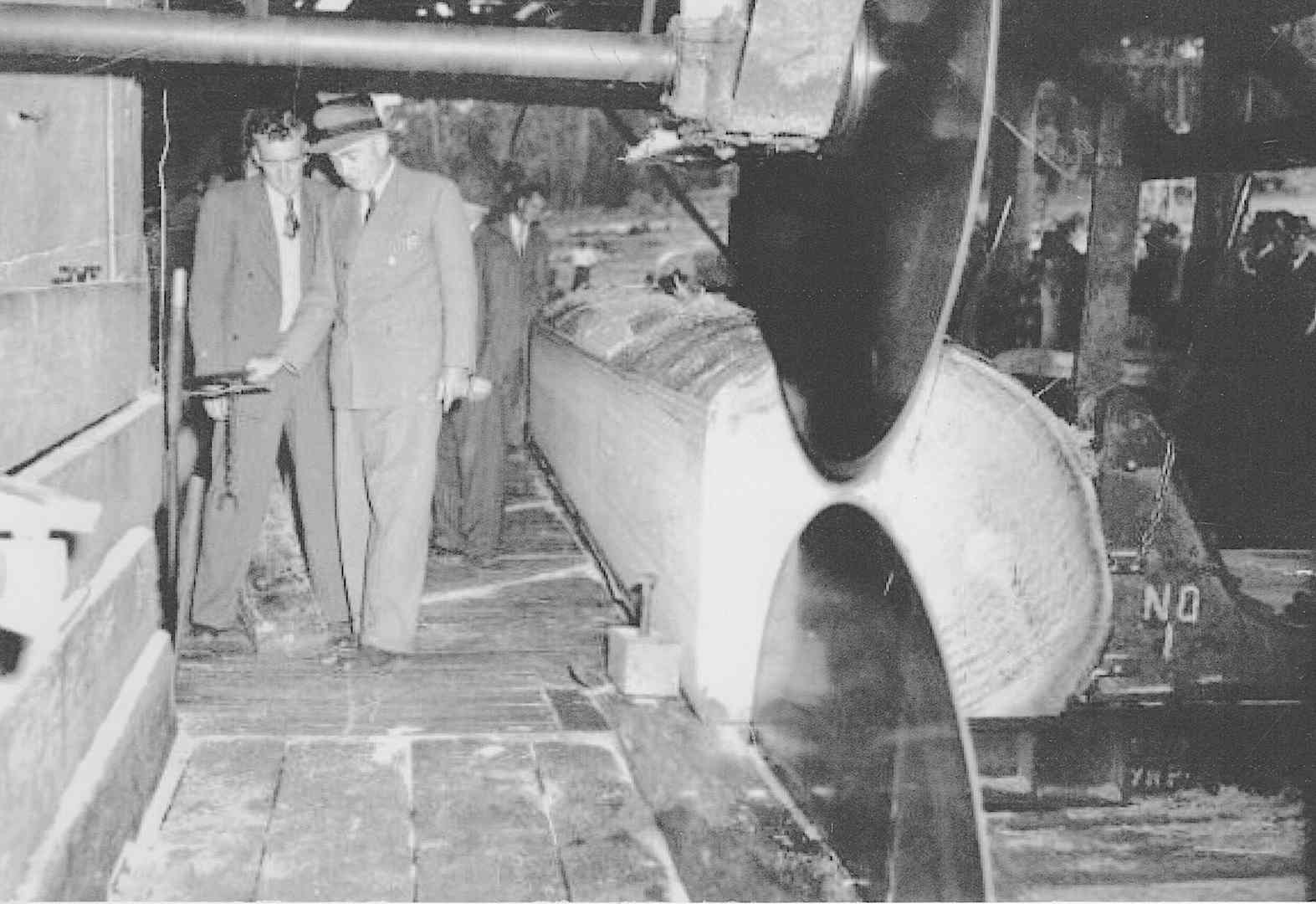

Due to the larger size karri timber in the forest, the mill was designed to be equipped with heavier equipment capable of handling the larger karri with logs up to 2.5m in diameter. To enable the large logs to be cut in a single pass, the mill was fitted with a large “twin saw”.

The twin saw was designed to make the first cut of the logs, creating flitches that were distributed to the various bench saws by way of the powered rollers.

The twin saw operator had the task of assessing each log and determining the first breaking down cuts to ensure the maximum amount of timber yield and the isolation of defective sections of the logs, and also consider the order in hand. The first log cut was the responsibility of the “spotter” or twin sawyer operating the twin saw, one of the most important tasks of sawmilling at the mill.